FSDP anticorrosive screw vacuum pump

Technical characteristics of FSDP anticorrosive screw vacuum pump

FSDP anticorrosive screw vacuum pump adopts special anticorrosive coating technology, which can resist all kinds of strong acid corrosion.

The material and coating standards of the equipment are particularly important. Let's introduce the material and coating standards of the equipment

Coating options

1. Special coating: nickel plating, Teflon, Hastelloy coating.

2. O-ring: perfluoroether rubber special mechanical seal, such as Hastelloy, high nickel corrosion resistant metal.

Texture of material

1. The pump body and end cover are made of ductile iron.

2. Synchronous gear: alloy steel, precision grinding, helical gear.

3. Rotor: fcd55 cast iron.

4. O-ring: fluororubber.

Product description

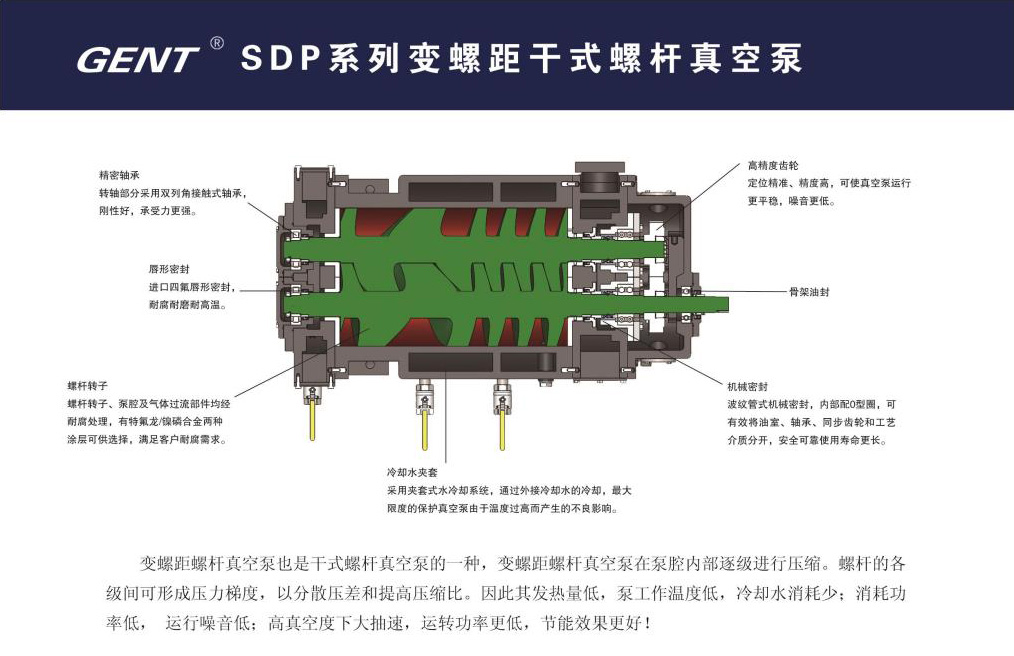

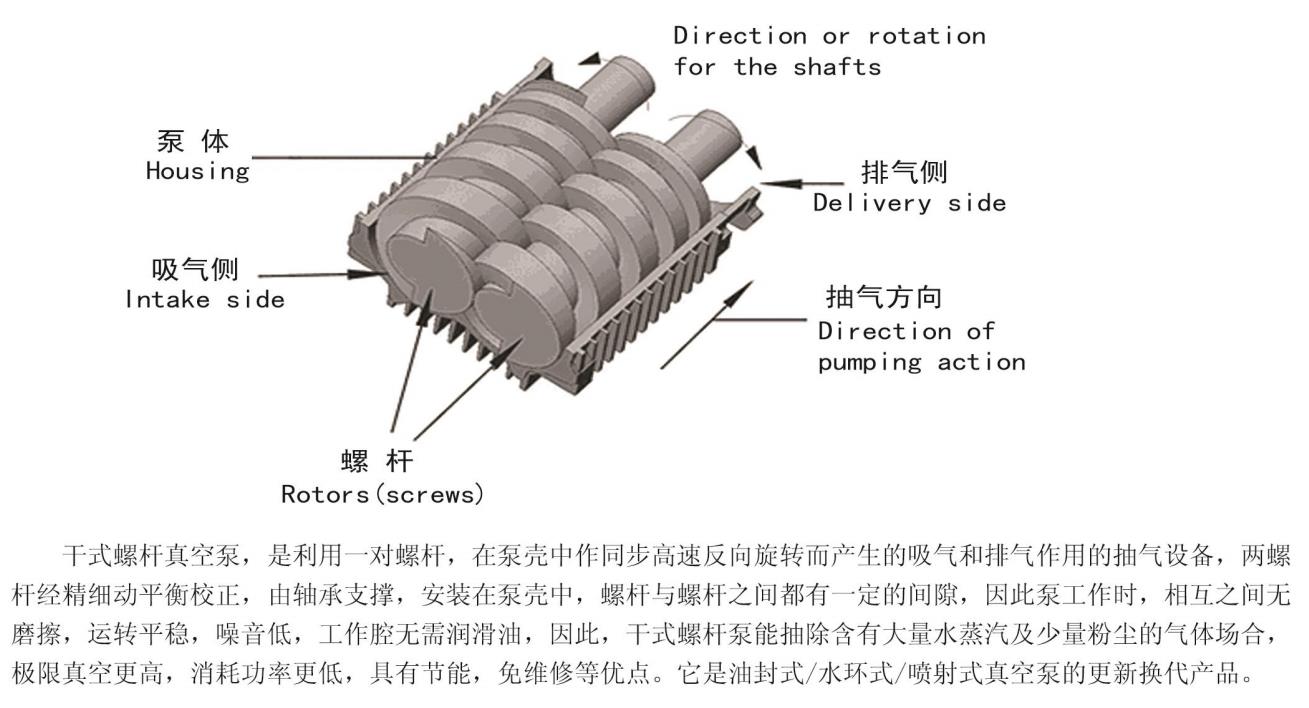

SDP variable pitch screw vacuum pump, also known as dry screw vacuum pump, is a workroom composed of a pair of parallel spiral rotors and pump body. There is no friction between the two screw rotors and between the two screw rotors and the pump body processed by the five axis linkage composite machining center, and a certain gap is maintained. A plurality of sealing cavities are formed between the two rotors and the pump body. The rotors are in the pump shell through the gear It is a kind of suction and exhaust equipment which can continuously push the gas in each seal cavity from the inlet end to the exhaust end during synchronous high-speed reverse rotation.

The working chamber of the screw pump is hermetically sealed without lubricating oil. It is an environment-friendly vacuum equipment. Therefore, the dry screw pump can pump out the gas containing a large amount of water vapor and a small amount of dust. It has the advantages of high limit vacuum, low power consumption, energy saving, consumption reduction and maintenance free, especially in the semiconductor and electronic industries where oil-free cleaning is required, and the solvent recovery process in chemical and pharmaceutical industries It has incomparable advantages.

Screw vacuum pump is the substitute of traditional water ring vacuum pump, water jet vacuum pump, reciprocating vacuum pump, slide valve vacuum pump, rotary vane vacuum pump and other vacuum pumps. The upgrading of this product can effectively eliminate the sewage discharge in the vacuum process of pharmaceutical and chemical industry, which is conducive to the recovery of tail gas solvent, and can also effectively reduce the oil vapor pollution of slide valve vacuum pump and rotary vane vacuum pump, and reduce the equipment cost Maintenance costs.

Working principle

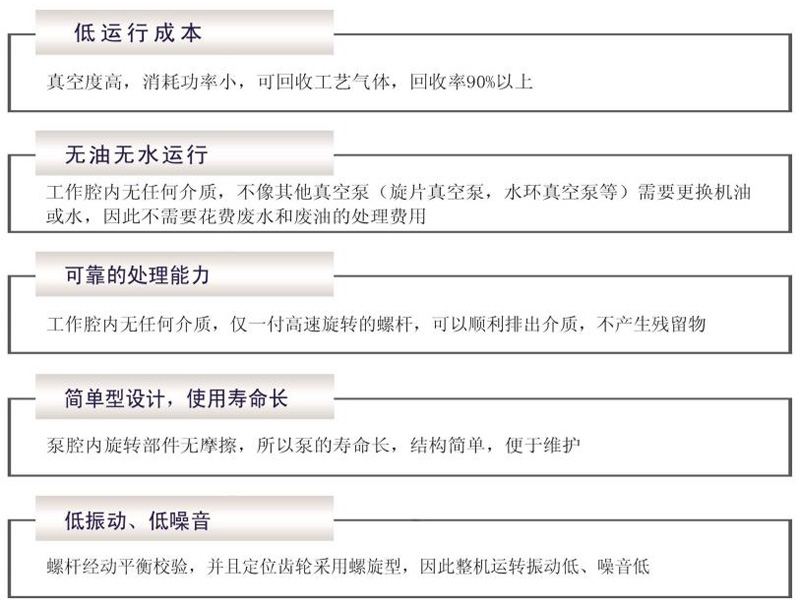

Performance characteristics